The significance of safety gratings for punching

Times:2018-03-12 Hits:409

The significance of safety gratings for punching

Now that the government has ordered dangerous punches to install safety gratings, what is the irreplaceable significance of safety gratings for punching machines? Safety light curtain punching machines can bring huge benefits to our factories, but punching machines are large machines. There are certain risks when running, so when operating the press, we will have a lot of safety measures to protect the safety of our employees. Here are some of the protective devices that are summarized to protect the press:

1. Two-handed operation safety control device: The operator must operate two buttons or switches at the same time with both hands, and the punching machine slider will run downwards. If it is released, any button slider will stop running immediately, thus ensuring the punching machine. When running down, the operator's hands are not in the danger zone, mainly two-hand button device and double-handle safety device.

2, safety button: in order to avoid hurting the operator's hand, and the press slider reaches the bottom dead center 100 ~ 200mm (can be selected according to the characteristics of the workpiece), the operator must press the safety button, slider Continue to go down, otherwise it will stop automatically, because an operation action is added to remind and protect the operator.

3. Combination of handle and foot pedal interlocking device: When the press starts working, only the handle is pressed by hand, the pin inserted on the starting rod is pulled out, and the pedal can be stepped on. Combine and make the press work, so that the operator's hand naturally leaves the danger zone before the press slide is lowered, and the injury accident caused by the malfunction of the foot in the danger zone is avoided.

4, protective cover and protective fence: the protective cover and fence to isolate the dangerous area, the operator's body can not enter the danger zone, thus avoiding the accident

5, handle safety device: by wearing on the operator's wrist with a wrist fastener made of nylon and other materials, wrist buckle through the handle rope and linkage mechanism and the press slider linkage, when the slider is down, can operate The hand of the person is pulled out of the danger zone to avoid the accident of injury.

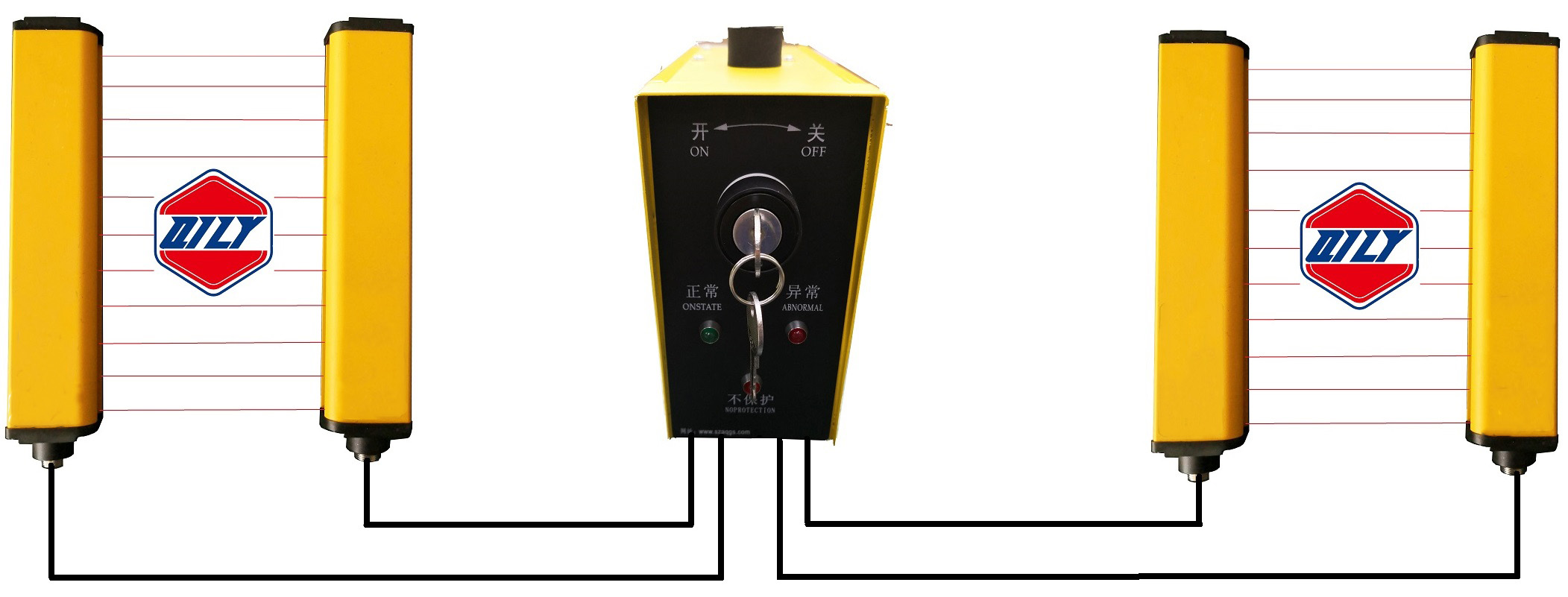

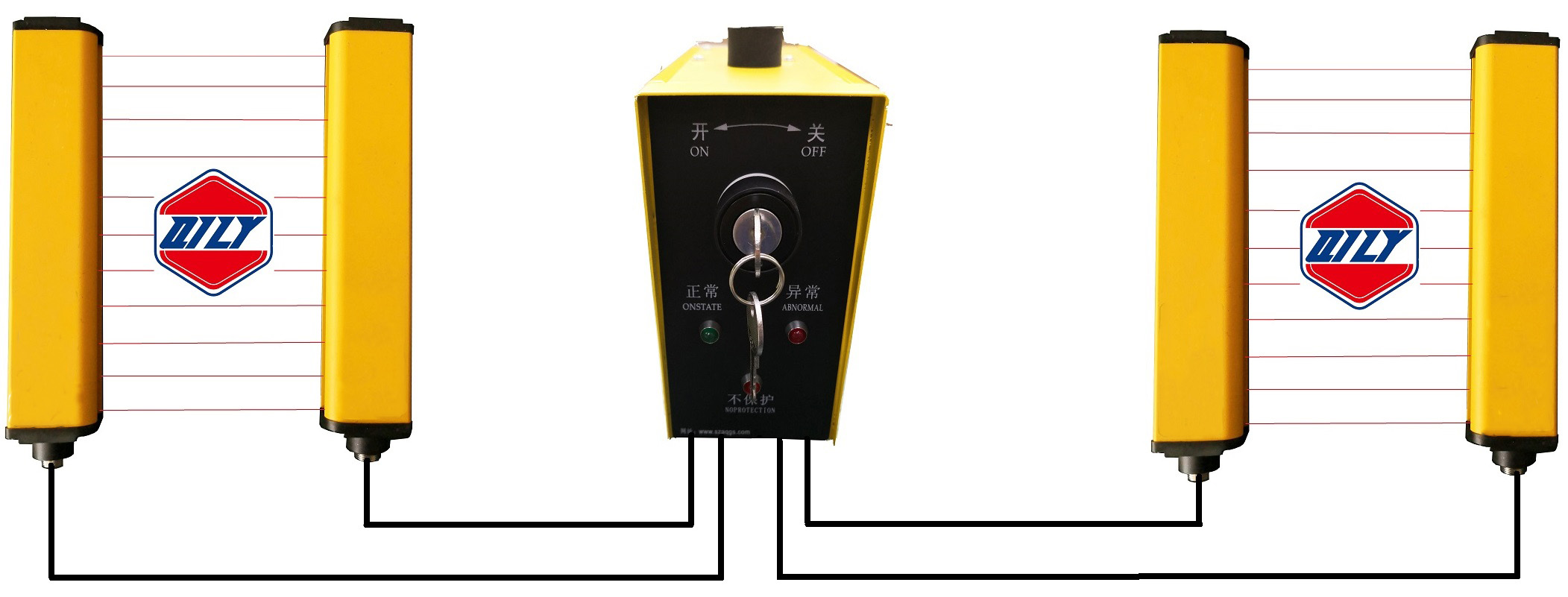

6. Photoelectric or infrared safety device (safety light curtain photoelectric protector): Install photoelectric or infrared emitting and receiving devices in the danger zone. When the human hand enters the danger zone, the light will be blocked and the safety device will brake immediately. Stop the slider down and ensure the safety of the manpower.

7. Pendulum type hand-carrying device: When the slider is down, a rubber rod that is linked with the slider will force the operator's hand to be safely removed from the danger zone.

8. Push-type safety device: Install the pusher board in front of the mold area, push the hand board back and forth during operation, and automatically push the hand out of the mold area to ensure the safety of the operator.

Tips: Punch is a dangerous machine, so we need to install photoelectric protection devices to protect the safety of our employees. The price of a set of safety gratings can vary from a few hundred to several thousand, a safety accident, and possible losses. It is tens of thousands, so if you don't install the safety grating, you should install it as soon as possible, the accident will happen, and you will be repaired again. You will not lose it!

粤公网安备 44190002004217号

粤公网安备 44190002004217号